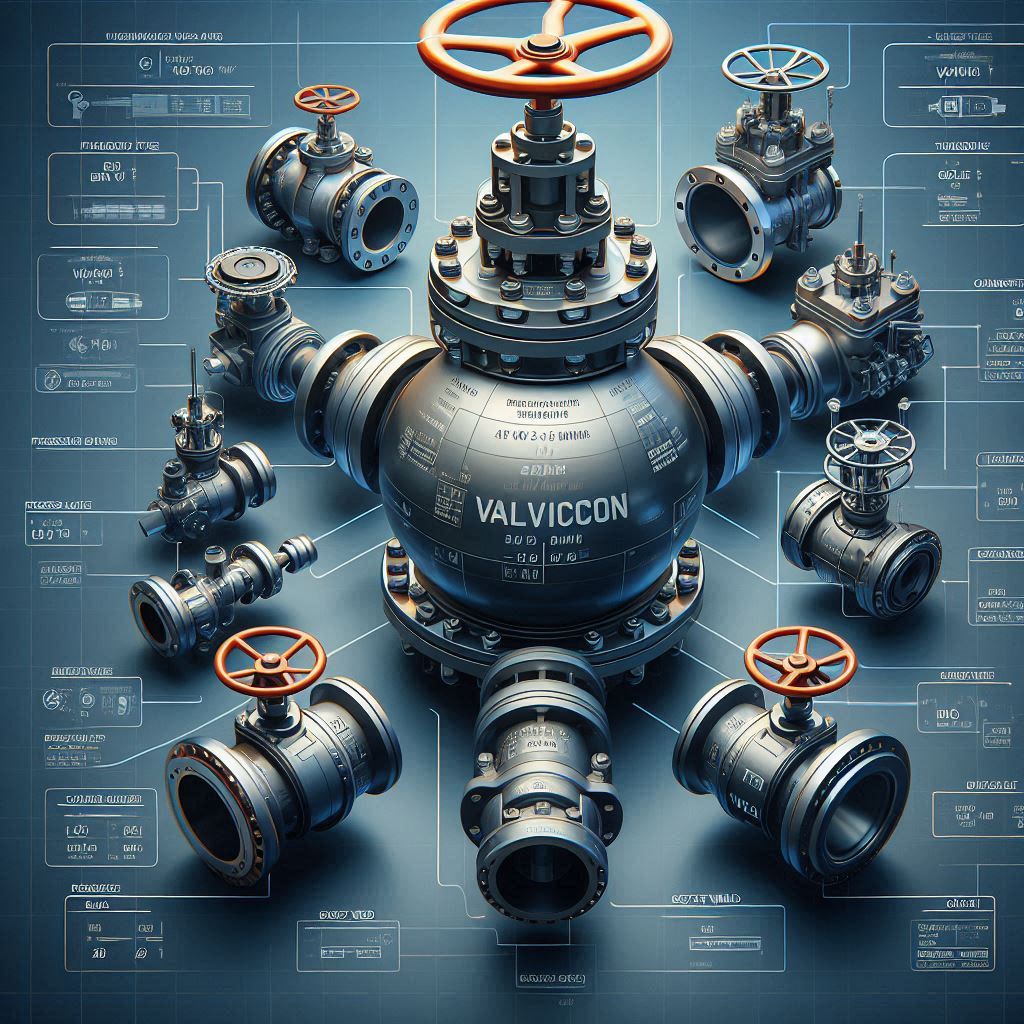

About Valvicon Industrial Valves

Valvicon India Pvt. Ltd. manufactures premium industrial valves designed for critical applications across various industries. As authorized dealers, we offer their complete range of ball valves, butterfly valves, gate valves, and globe valves available in pressure classes from 150 to 1500, constructed in carbon steel, stainless steel, duplex stainless steel, and Inconel alloys.

- Full range of valve types for all industrial needs

- Available in cast and forged constructions

- Optional pneumatic or electric actuation

- Designed for high-pressure and high-temperature applications

Valvicon valves are engineered for reliability in the most demanding environments, from refinery applications to chemical processing plants. Their products undergo rigorous testing to ensure leak-proof performance and long service life, making them the preferred choice for engineers across industries.