About J D Jones Gland Packing

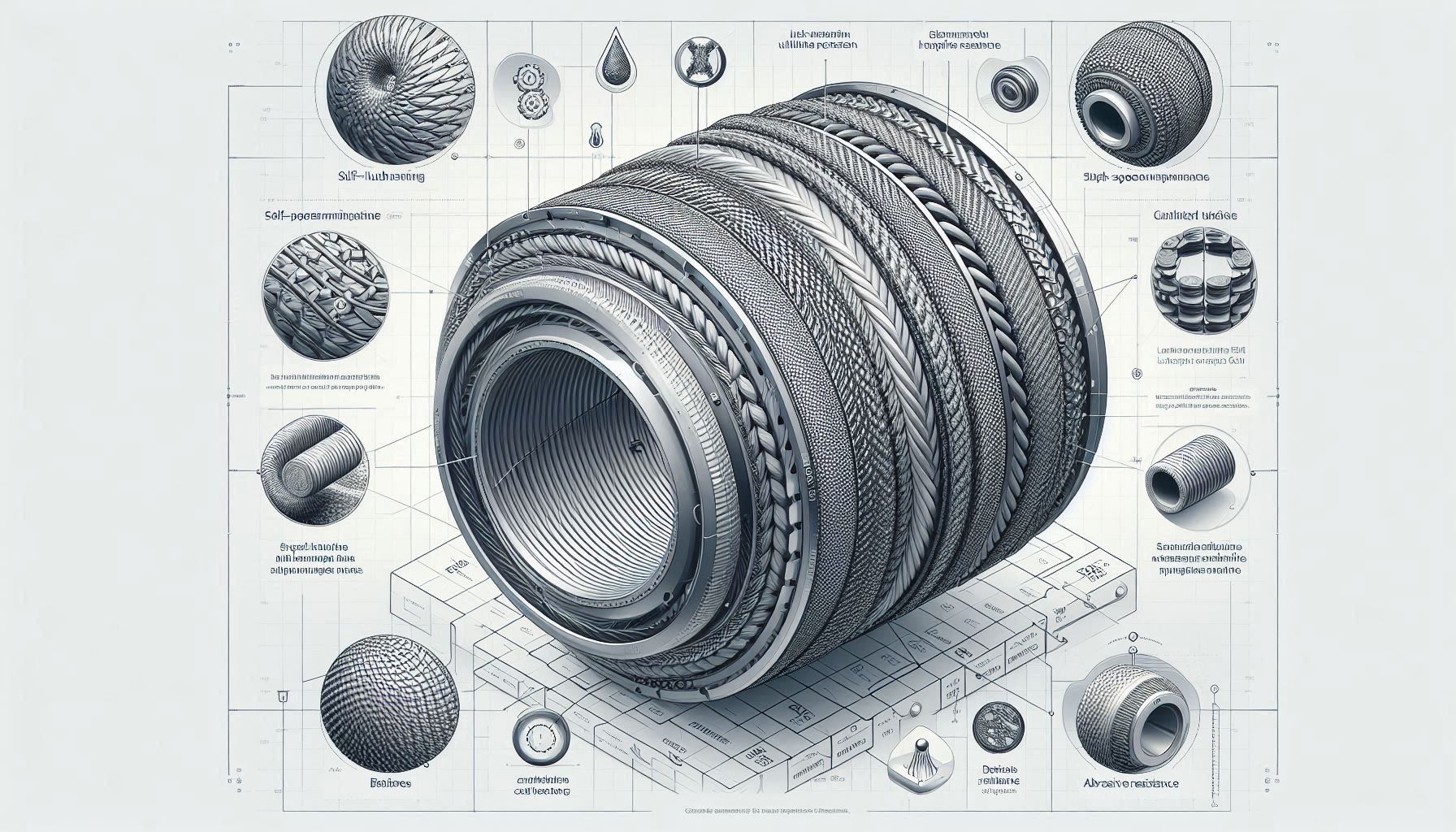

Established in 1950, J D Jones is a global leader in gland packing technology, manufacturing superior compression packing products for demanding industrial applications. Their engineered sealing solutions handle extreme pressures up to 550 bar and temperatures ranging from -100°C to +1000°C across virtually all media types.

- 70+ years of sealing expertise

- Compatible with all industrial fluids and gases

- Low-friction formulations for reduced wear

- Extended service life with minimal maintenance

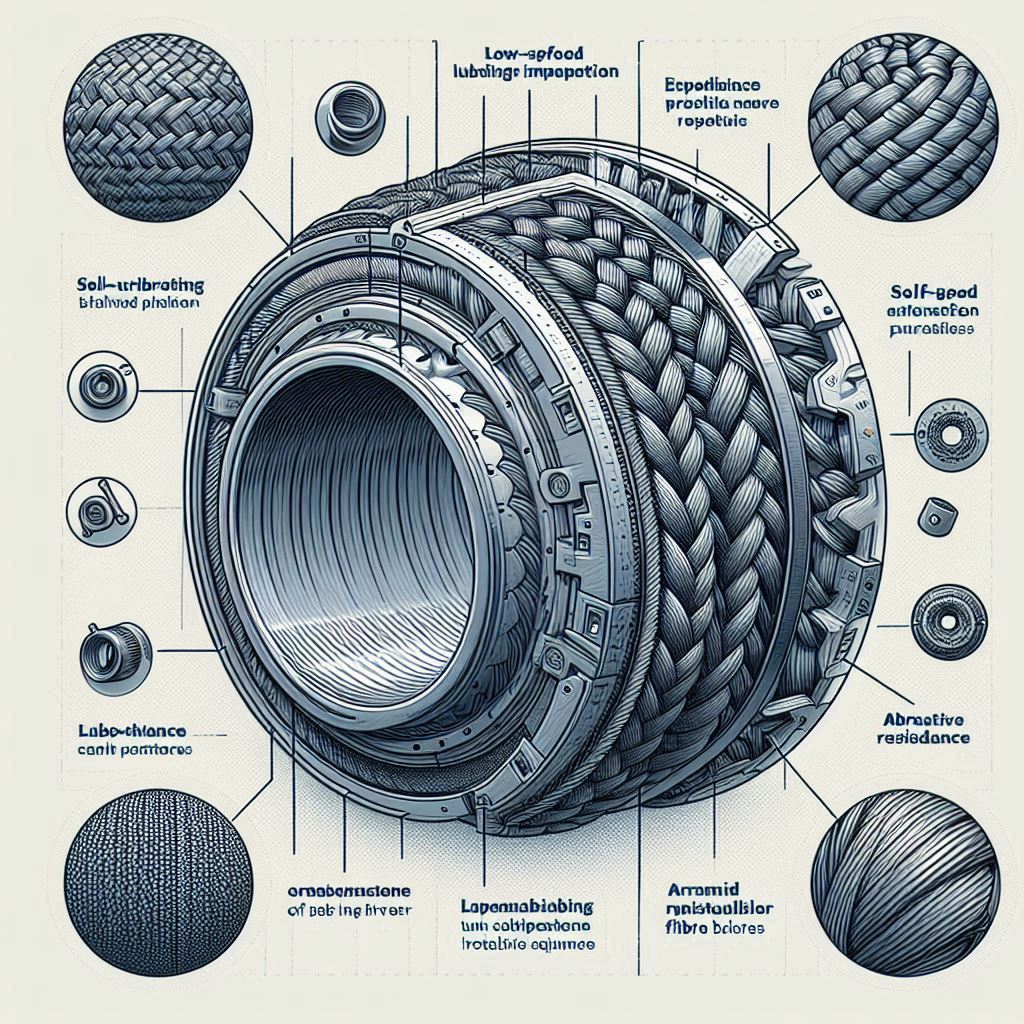

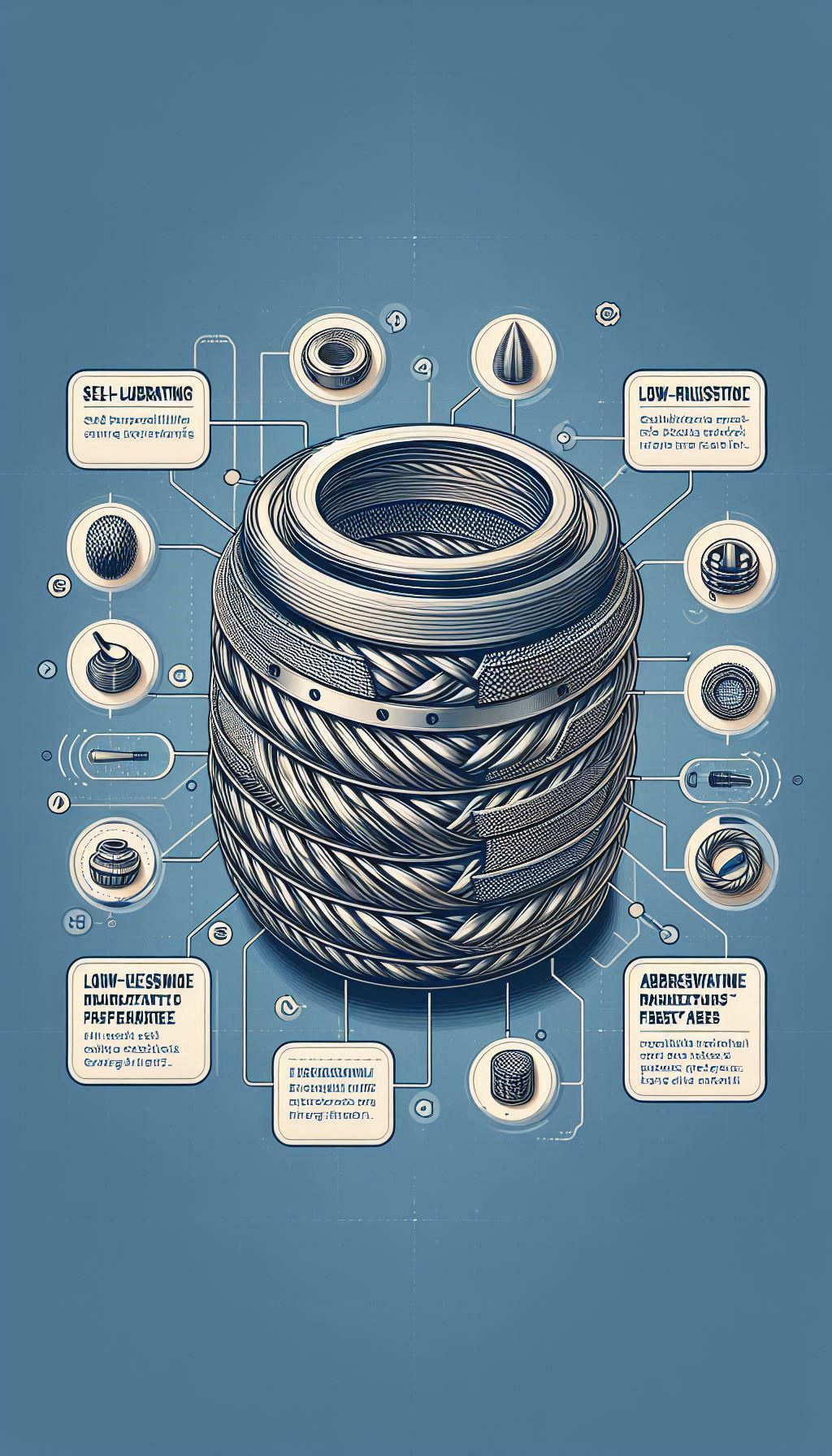

J D Jones packing products are engineered to provide reliable, leak-free performance in pumps, valves, and rotating equipment. Their innovative material combinations and braiding techniques create packing solutions that outperform conventional products, reducing downtime and maintenance costs.