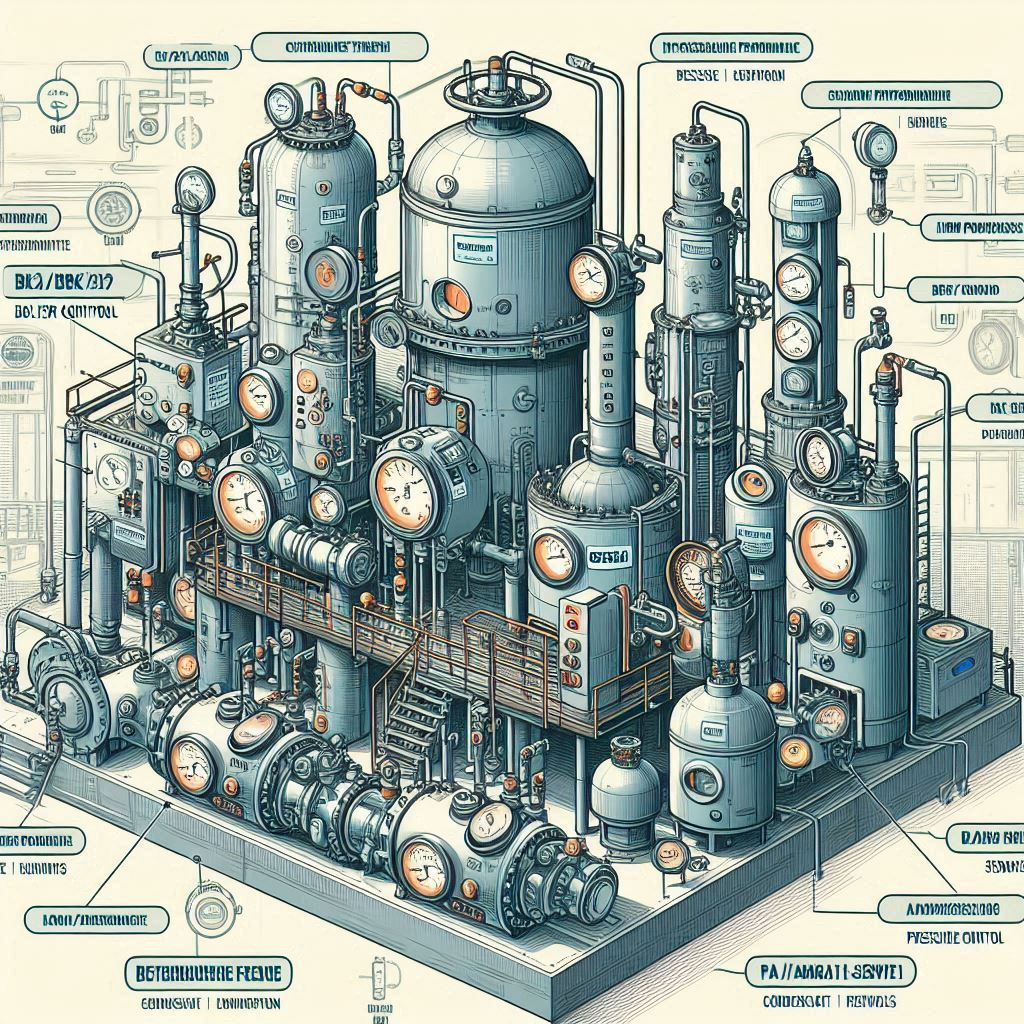

About Gestra Valves

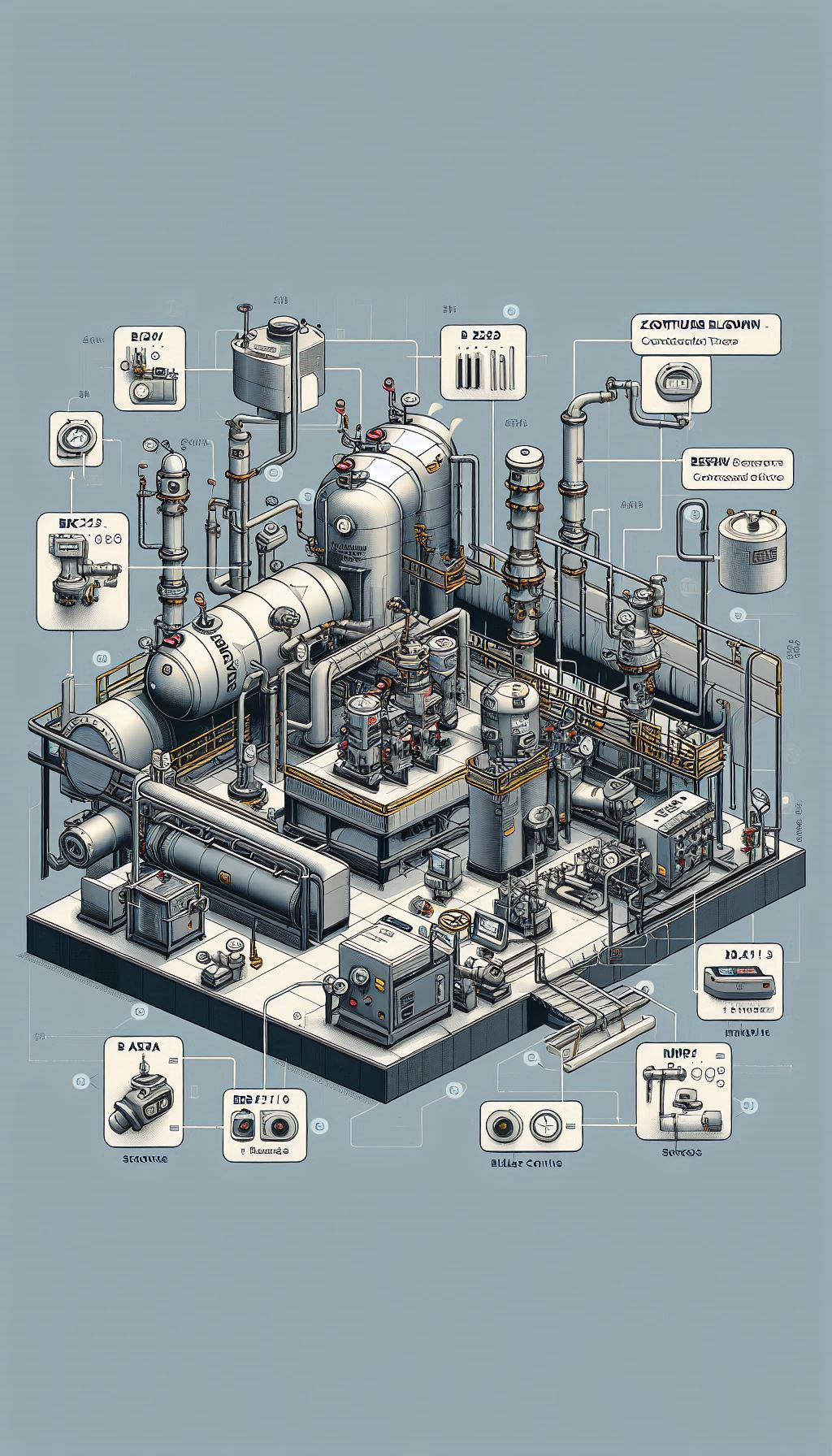

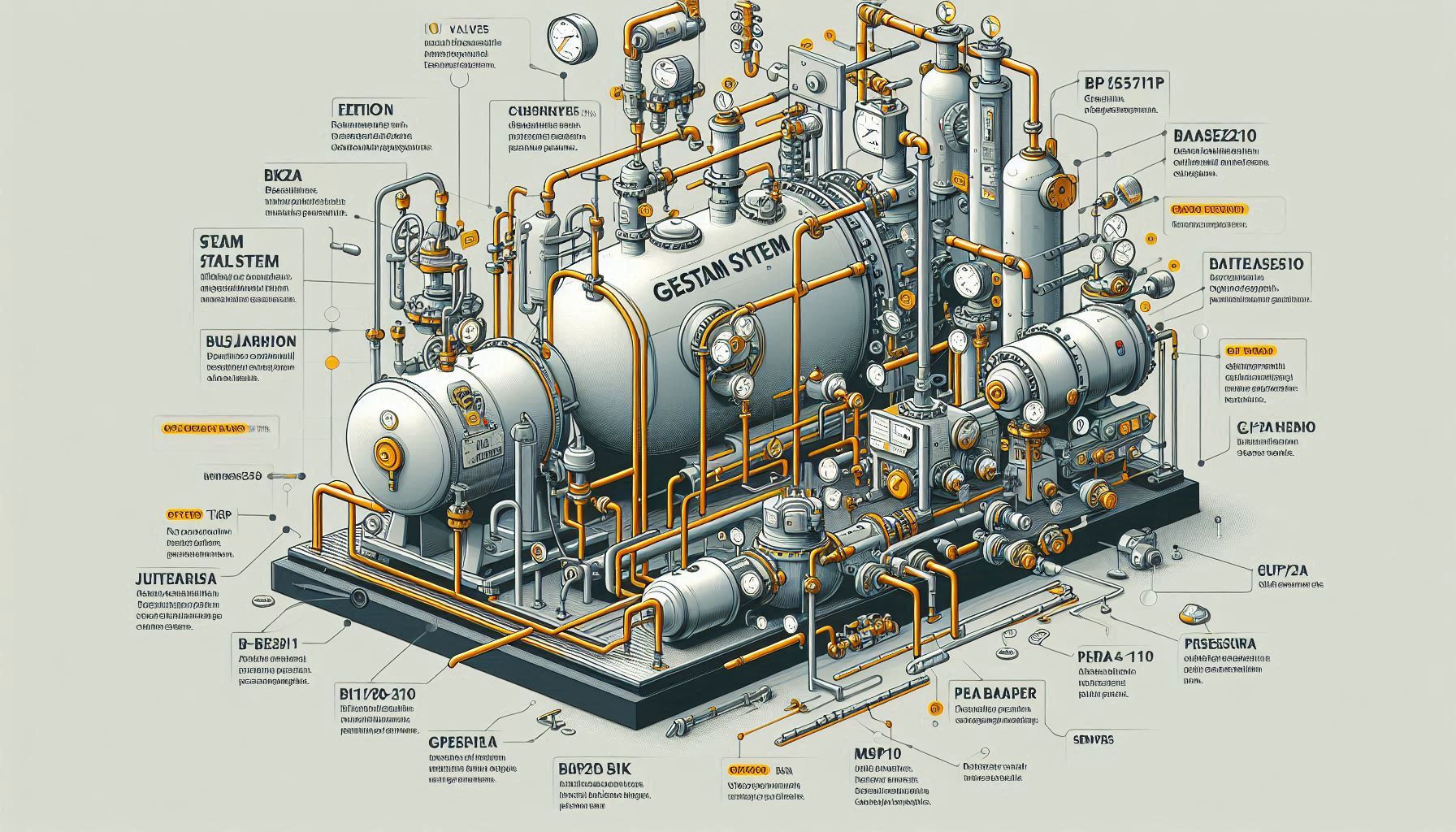

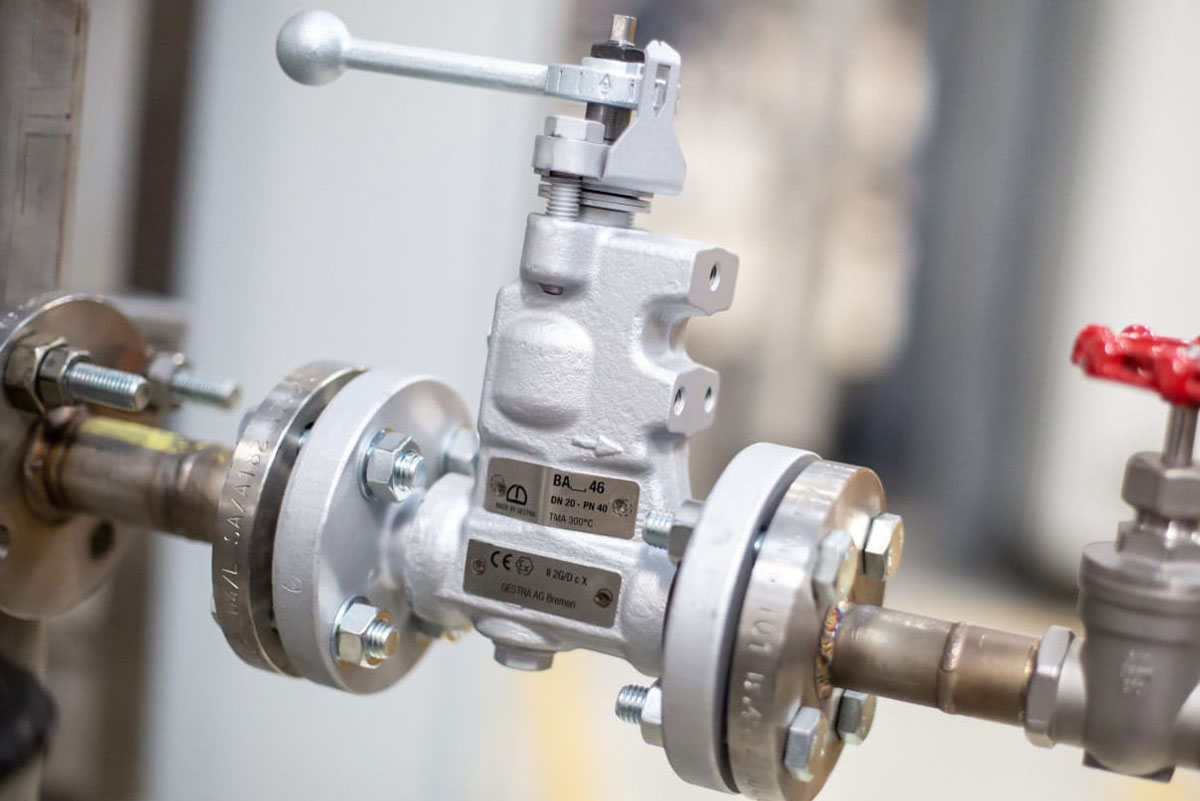

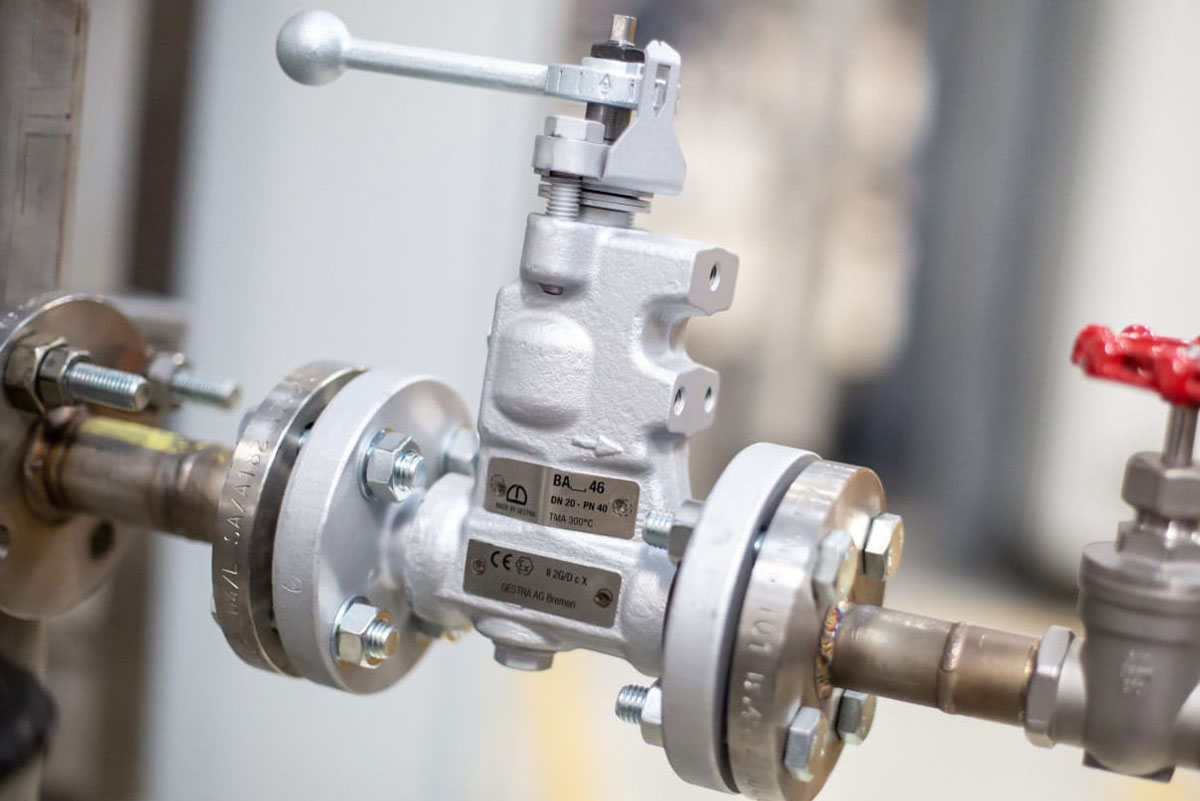

Gestra, established in 1902 and headquartered in Bremen, Germany, is a world leader in industrial steam system valves and controls. Their products are engineered for precision performance in critical applications across power plants, refineries, and chemical processing facilities.

- 120+ years of steam system expertise

- Continuous Blowdown (CBD) and Intermittent Blowdown (IBD) valves

- High-performance steam traps and check valves

- Severe service applications specialists

Gestra's ZK valves are specifically designed for continuous blowdown applications where flow rates exceed 3 t/h, while their BK series steam traps are optimized for turbine areas and steam mains. The company's solutions help industries maximize steam system efficiency while ensuring operational safety.