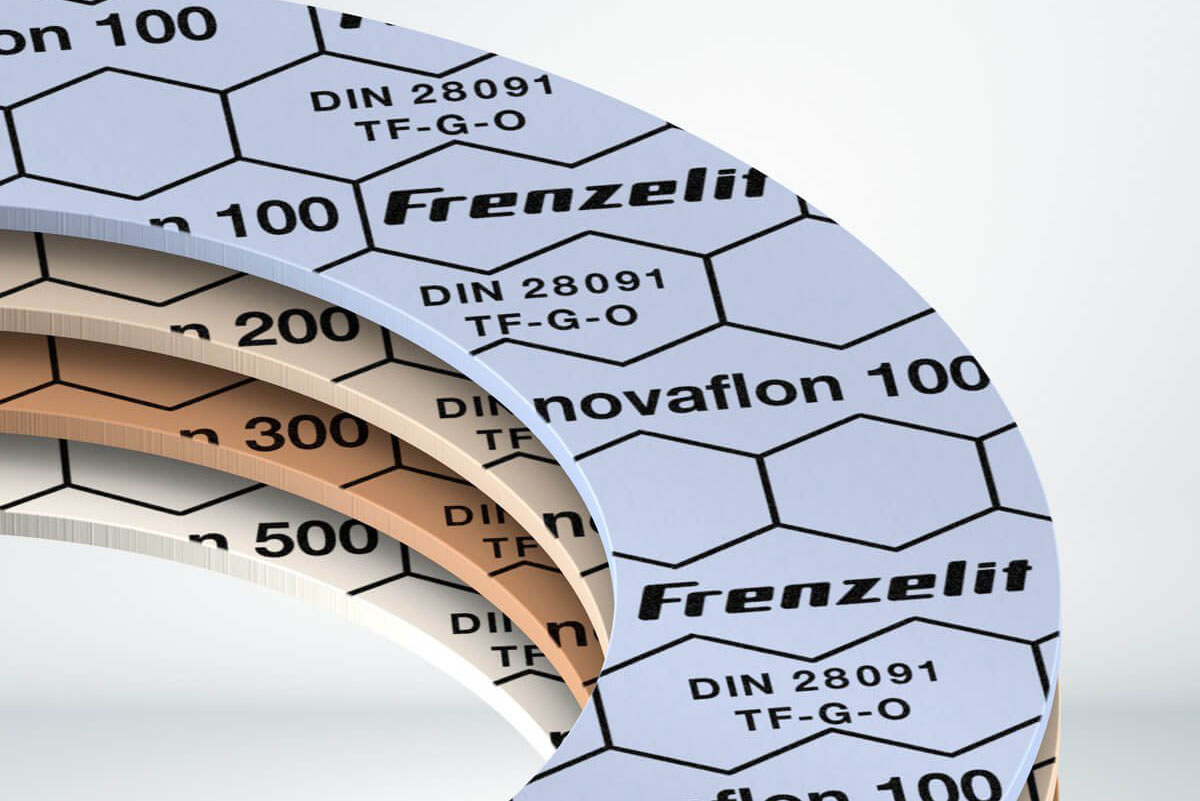

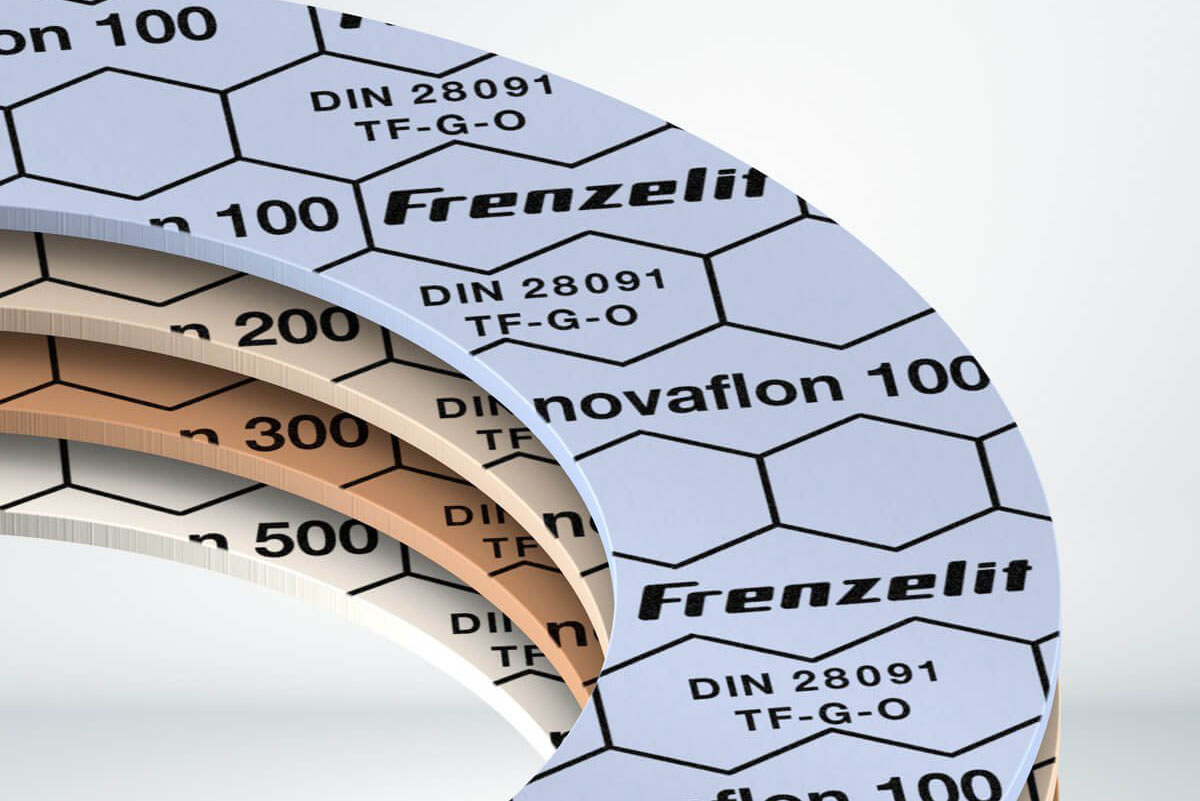

About Frenzelit Gaskets

Frenzelit, a Germany-based manufacturer, produces premium non-asbestos gaskets engineered to withstand extreme temperatures and pressures. These high-performance sealing solutions are designed for critical applications where standard gaskets would fail, offering exceptional chemical resistance and long-term stability.

- 100% asbestos-free compositions

- Exceptional thermal and chemical resistance

- Available in sheets or custom pre-cut forms

- Low creep relaxation for maintained sealing force

Frenzelit gaskets utilize advanced composite materials that outperform traditional sealing solutions. Their unique formulations maintain integrity in harsh environments, from high-pressure steam systems to aggressive chemical processes, making them the preferred choice for industries demanding reliable, long-lasting seals.