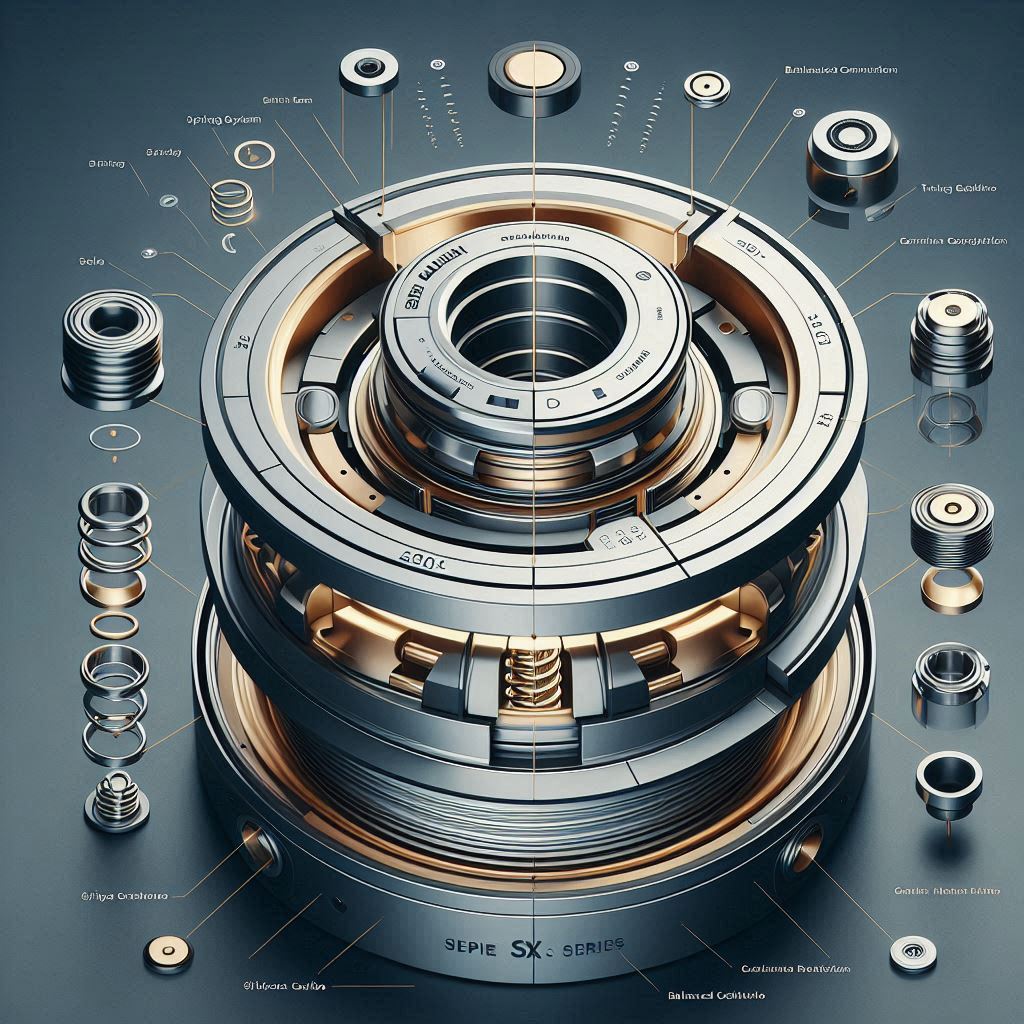

About Sealmatic Mechanical Seals

Sealmatic India Pvt. Ltd. is a publicly listed company and leader in manufacturing high-precision, high-performance mechanical seals for rotary equipment. As authorized dealers, we provide their complete range of mechanical sealing solutions designed to prevent leakage in pumps, compressors, and other rotating machinery across critical industries.

- Engineered for zero leakage in critical applications

- Custom solutions for extreme operating conditions

- Compliant with international standards including API 682

- Extended mean time between failures (MTBF)

Our Sealmatic mechanical seals are designed with advanced materials and precision engineering to handle the most challenging sealing applications. From standard single seals to sophisticated double and tandem arrangements for hazardous fluids, Sealmatic offers reliable solutions that reduce maintenance costs and improve operational safety.