About Tuthill Vacuum Solutions

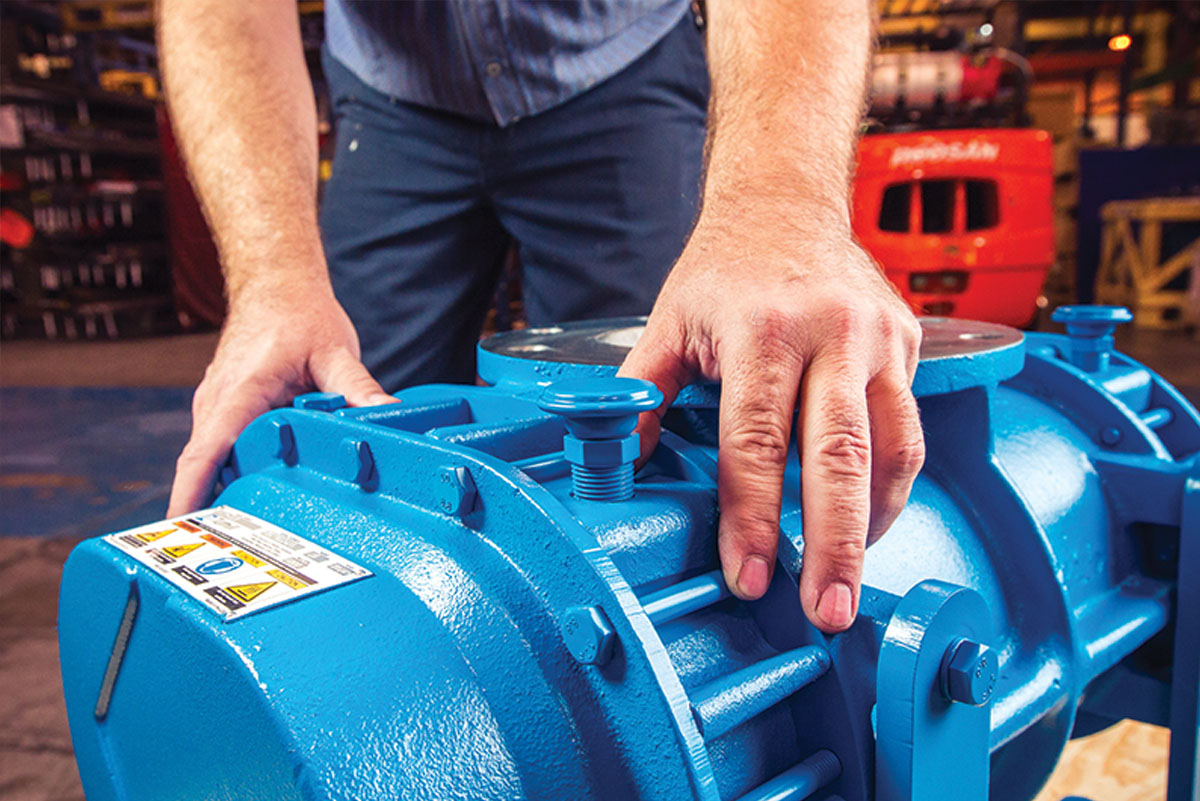

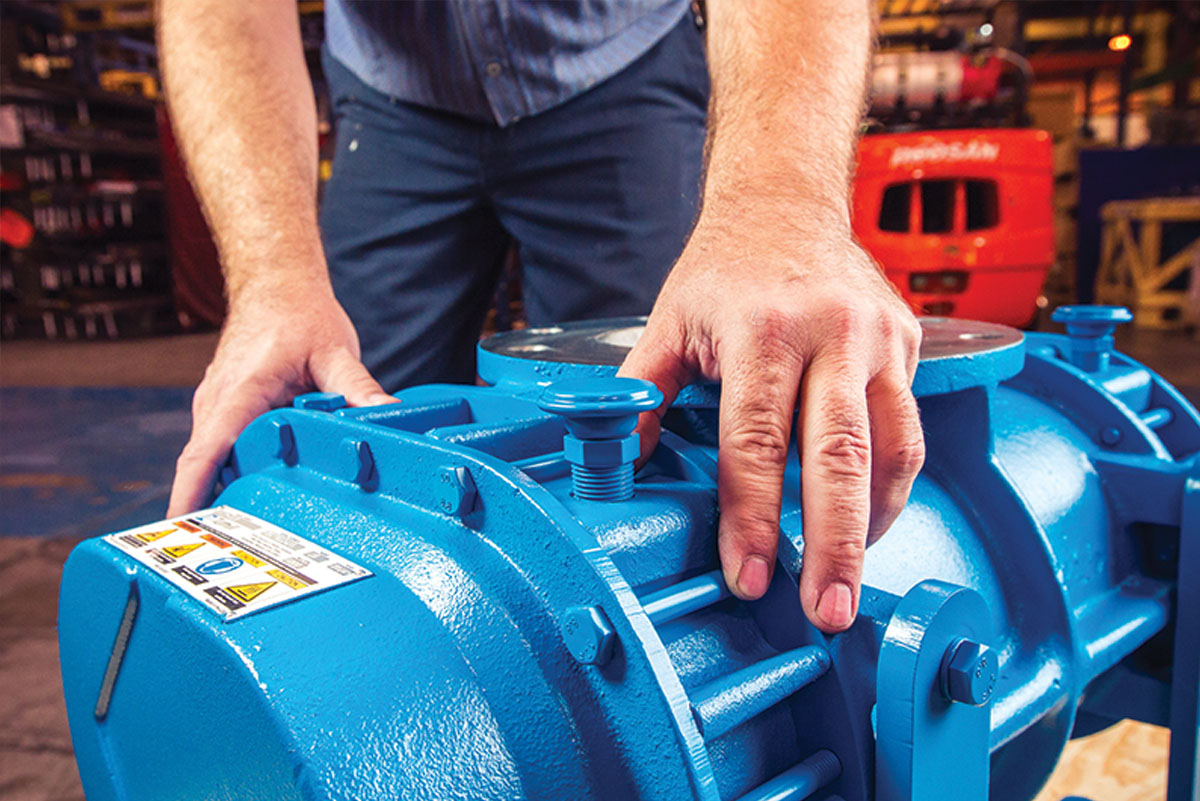

Since 1892, Tuthill Corporation has been a pioneer in vacuum technology, manufacturing high-performance vacuum pumps and systems for industrial applications worldwide. Their solutions range from standard vacuum pumps to custom-engineered systems designed for specific process requirements.

- 130+ years of vacuum technology expertise

- Both standard and custom-designed solutions

- Oil-sealed and dry vacuum pump options

- Complete systems with controls and accessories

Tuthill's vacuum products are engineered for reliability in demanding industrial environments. Their pumps deliver consistent performance in applications ranging from food processing to semiconductor manufacturing, with options for various flow rates, ultimate vacuum levels, and specialized configurations.