About Fainger Leser Valves

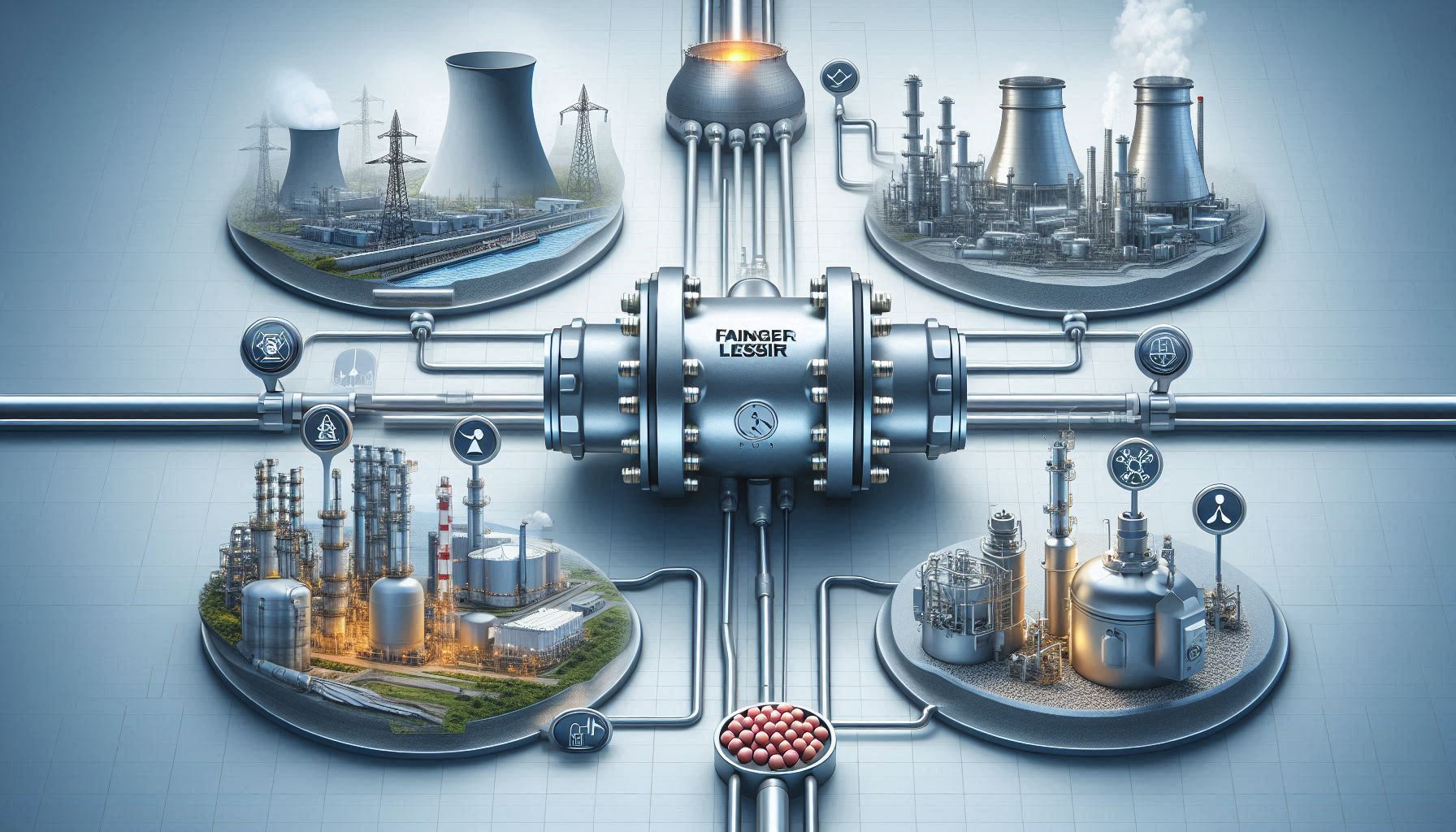

Fainger Leser Valves Private Limited, established in 1987, is a German multinational and leading manufacturer of high-quality industrial safety valves. As authorized distributors, we bring you their premium products including the FL 441 Sp Universal Safety Valve, FL 237 Series relief valves, bellow sealed valves, and pressure relief valves (PRVs) - all manufactured to exacting German standards at their state-of-the-art facility in Aurangabad, India.

- German-engineered precision for critical applications

- Manufactured in India for cost-effective solutions

- Wide range of safety and relief valve options

- Serving nuclear, chemical, and oil & gas industries

Our Fainger Leser valves are designed to meet the most demanding industrial requirements, offering unmatched reliability in pressure management and safety systems. With decades of R&D and field testing, these valves represent the pinnacle of safety valve technology, combining German engineering excellence with localized manufacturing advantages.